Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- Biomass boilers and system sizing

Biomass boilers and system sizing

The factors to consider when sizing a biomass boiler system, including the weekly heat demand profile.

Back to: An introduction to biomass heating for horticulture

How and why should I size my system?

In order for a boiler system to be fully utilised, it is essential to consider the sizing of the system with respect to heat demand. This is complicated, because it involves balancing capital cost, returns from the Renewable Heat Incentive (RHI) and costs of fuel.

Weekly heat demand profile

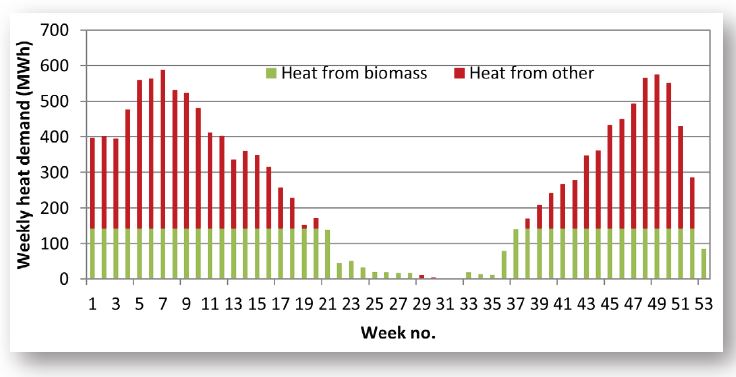

To work out viability, it is necessary to look at the weekly profile of heating energy use and the potential delivery of the boiler. CO2 recovery from the flue gases of a biomass boiler for greenhouse environment enrichment is currently not possible. This reduces the potential heat offset. The diagram below shows a typical profile for an edibles grower. By using a biomass boiler to cover, say, 25% of peak demand, the boiler can be operated at full output for over 70% of the year.

Weekly heat demand profile

Ornamental crops growers who do not require CO2 enrichment can offset all of their heat demand by installing a biomass boiler system and, by doing so, make excellent returns on investment. This is especially true where the fossil fuel being substituted is oil. The use of buffer tanks (heat stores) helps in spreading heating load and optimising boiler size. The recommended size for a buffer tank is between 50 to 150 litres of water per kW of boiler size.

Edibles growers are used to this idea, as they use buffers to facilitate storage of heat during CO2 production. However, it’s more of a novelty for ornamentals growers, who have not used the technique as much.

Biomass boiler emissions

There are flue-gas emission standards required for Renewable Heat Incentive (RHI) eligibility.

Boilers are continually improving in terms of materials handling and cleanliness of burn. However, flue-gas emission standards were introduced for Renewable Heat Incentive (RHI) eligibility from 23 September 2013.

The standards are:

- NOx limits of 150 g/GJ energy

- Particulates less than 30 g/GJ

Proof of compliance is required when applying for accreditation under the RHI scheme. Meeting these standards might be challenging for some systems. Some straw boiler designs will struggle to meet the NOx limits and some will more than likely need filtration to reduce particulates.

Useful links

Visit our GrowSave pages to read more about energy-related topics

Topics:

Sectors:

Tags: